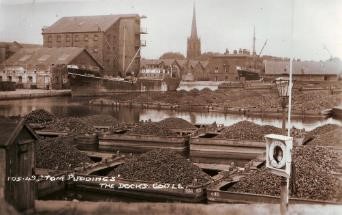

Tom Puddings

Goole's success as a port came from its ability to compete with the railways to export coal from the Humber. This was achieved by a system of compartment boats developed by William Bartholomew in 1863. They were locally known as "Tom Puddings" ("Tom" meaning something large and "Pudding" because they compartments looked like intestines or a string of sausages or black pudding) and consisted of long trains of compartments which could hold around 40 tons of coal each. The compartments were lifted into awaiting ships at Goole via hydraulically operated hoists. Between 1863 and 1912, five hoists were used at Goole to cope with the enormous tonnage of coal. The system continued to be used up to 1986.

Normally trains of 21 compartments were used, although sometimes up to 38 could be carried in one go. The compartments often floated at different levels depending on the type of coal being carried. The front few compartments were usually not fully loaded to make the barge propeller more efficient. The limiting factor was the size of the locks (trains often had to be split) and any side winds which could skew the train too close to the bank.

Originally locks were between 215 and 265 feet long which allowed about ten compartments through in one go. Eventually all the locks from Goole to Castleford were increase to 450 for a maximum of 19 compartments. Sometimes union agreements limited the size of the boats.

A large number of empty compartments and tugs were based at Goole. Collieries would inform Goole daily with their requirements. This allowed empty trains to go from Goole and be efficiently distributed between the different collieries and to ensure there were enough spare compartments to go round.

In the busy periods a tug would only have to visit one colliery, but later they had to call at two or three to be economical.

At the colliery, each compartment was dragged up from the canal onto a railway bogey running on an underwater railway track. These were then taken by an engine to the colliery for the coal to be loaded.

Once it was loaded, the locomotive would push the compartment back into the canal where it would float off the bogie and could be shackled together into a boat train and towed to Goole. The system became known as the "Railway on the Water". It was so economical that the cost of transporting coal this way was far cheaper than the railways or other canals in the country.

When they were towed, the compartments were held together by chains. An axe was kept handy to cut the chains as if one compartment sank, it could drag the others down. Each compartment had a walkway to allow the boatmen to move around. A leader or jebus was attached to the front of the tug to act as a breakwater. The tugs were originally steam-powered and just given numbers, but were later powered by diesel and named after the collieries they served.

Once the compartments arrived at Goole, they were split up and stored ready to meet the demands of the outgoing ships. At peak times over 200 compartments could arrive at Goole each day. South Dock and Ouse Dock were used as storage places and could hold up to 800 loaded compartments sorted on the grade of coal they were carrying.

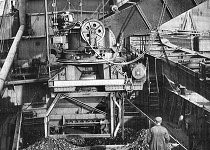

The hoists at Goole were 90 feet high. No.1 was built of wood and the rest of steel. A cage was lowered to below the water level and a loaded compartment was moved over it. At the same time hydraulic pistons could move the empty one out of the way. The loaded compartment was then secured to the cage and the whole thing raise to the required height for the ship. Another pair of pistons then rotated the case 125 degrees to allow the coal to tip out into the ship's hold. Two "spout men" would use shovels to ensure no coal was left behind.

In the early days the hoists could handle around 100 tons of coal per hour. This increased to around 300 tons per hour as the design of ships' holds improved. The fastest loading was in 1947 when the "Lady Sheila" loaded 251 tons in half an hour and arrived and sailed on the same tide.

Sometimes the compartments would carry bunker coal for the steamship itself. In most cases this had to be shovelled manually into a skip which was then loaded into the ship's bunker. It would take four men half a day to empty a compartment.

Hoist work was controlled at Goole by a Coal Inspector, two assistants and six Hoist Foremen. The Foremen checked which compartments needed tipping and would write the name of the ship with chalk on the side of the compartment. The spout men would then know which order to do the work.

It was often a Health and Safety nightmare, with the hoist operator having instructions shouted to him which he could not hear and inadequate lighting when working at night. The tug men were notorious for turning up to work drunk and they often went poaching on the riverbanks to try and supplement their income.

No. 4 hoist was originally a floating hoist that could be moved from one part of the docks to another. It was built in 1910 and dismantled in 1968. Various devices were used to keep the coal in good condition. These ranged from devices at the collieries to covers on the compartments which were important to keep certain types of coal dry. Most coal damage came when it was tipped by the hoist into the ship's hold. Anti-breakage devices were tried at the end of some hoists, which would gently lower the coal on small conveyor belts, but they were fiddly to use. In the end the cheapness of the system was more important than the quality of the product.

Coal was not just transported via compartments. Railway Dock had a high-level railway coal drop run by the L&YR. Wagons would enter along a high-level railway line, be tipped in to ships, and returned via a low line.

The use of Tom Puddings ceased in 1986 due to reduced markets. The final shipment was made to the MV. Dimple with coal from South Yorkshire ending a system with 122 years of use carrying 55 million tons of coal. Of all the five coal hoists that Goole had, only hoist No. 5 remains intact and is now a preserved building used as part of the waterways museum. There are also the diesel tugs, two jebuses and four compartments in existence. Hoist No. 3 was demolished in 1993 as part of dock expansion, although the controls were preserved for display.

The last compartments were built in 1977. Accidents sometimes happened with ships hitting loaded compartments and sinking them. This was made worse if they were tied together in dock as one sinking could bring down many others. In the worse accident, sixty loaded compartments sank in Ouse Dock in 1960. Sunken compartments were recovered by lifting them up with chains or screws, or in extreme cases by lowering the water level in the docks.

The Romance of Export - The Story of a Journey Overseas with Yorkshire Coal

Postcards

Visitor Comments

Posted by George on 25/03/2006

One of the former steam Tom Pudding tugs, WATERLOO, has been found lying derelict in the River Medway near Chatham. If anyone has a pot of spare cash it could be brought back for the Waterways Museum!

Posted by Colin on 27/04/2006

There's a Tom Pudding down old harbour (River Hull) being made into a houseboat. A bit small I thought.

Posted by Leofwine on 08/07/2010

I have some photos of the wreck/remains of the Tom Pudding tug Waterloo (originally No. 6) built by Thomas Scott in 1891. The tug is just off Horrid Hill in Gillingham, Kent on the River Medway.

Posted by Gordon on 12/07/2006

There is a very good section on W.H. Bartholomew and all his innovations for Goole in the book "Slow Boat through Pennine Waters" by F. Doerflinger (1971) giving a summary of the puddings. He mentions the ability to partially steer them by compressing the spring buffers separating the compartments by means of tightening the steel ropes on the appropriate sides. The book includes a fairly good reproduction of an illustration from The Graphic now held by the Garside Collection of the No. 5 hoist in action.

Posted by Elaine on 09/11/2006

I wish the internet and this site had existed in 1976! I dragged my other half all round the system looking for a Tom Pudding (he'd been laughing at the name) and there wasn't one around at the time.

Posted by Mike on 24/12/2006

When the boats were laden, I believe from fallible memory (late 1940s - early 1950s) that the Jebus was coupled behind the tug, but when they were empty, then it was coupled in front as a false bow, when the leading boat would be "cocked up" ie. the front aspect would be slightly raised. (Where else have I heard that phrase in connection with Goole?). I was told that the position of the Jebus was altered in order to create a flow down the sides of the boats to help maintain a less deviating path, and the "cocking up" lessened drag.

Incidentally, does anyone out there know the origin of the use of the word "Jebus" in this connection?

Posted by FH on 01/04/2007

I served my apprenticeship at Goole Repair Yard, known locally as the Top Yard. This was situated on the Dutch River side about 400 yards before the timber pond and the then called Smiths boatyard. It had a "pan" shop, a boiler shop, a fitting shop, carpenter's shop, blacksmith's shop, sawmill, tinsmith's shop, sailmaker's. It boasted a dry dock and slipway for winching flyboats/barges out of water. The inlet from the canal was approx 500 yards upstream of the No. 3 dry dock which was situated adjacent to the old gas house at the back of the "Cape of Good Hope" public house. Its function was to repair compartment boats (or "puddings"), jebuses (or leaders to give them their correct name), tugs (of which there were originally three long tugs used for towing flyboats and approximately seven or eight tugs for towing the strings of "tom puddings" up and down the canal).

When I started my apprenticeship all the tugs were steam-driven reciprocating engine vessels and were all riveted construction, as were the "puddings". The compartment boats were floated into a small cut at the end of the pan shop and then an overhead crane picked them out of the water and deposited them on four blocks which stood them about four feet off the floor, from which position they were repaired. The "pan shop" could hold approximately twelve pans and they were worked on in rotation with two or three pans a week being repaired. Boiler work was also under taken and shell repairs on the tugs and barges as required.

Without this yard the coal trade would have come to a grinding halt and yet strangely there seems to be no mention of it.

Posted by Jim on 15/05/2007

If this was top yard what was bottom yard?

Posted by FH on 02/07/2007

Top Yard. The name above has always been applied to the repair yard, which was then (in 1949) a part of the Aire & Calder navigation, and was subsequently part of the nationalisation of many industries. It subsequently was called the DIWE (divisional inland waterways engineering) or executive. The yard manager at that time was Mr Charles Marland and he was superseded by Mr Leslie Pearce, the well-known Goole Town cricketer. The timber pond was a shallow area some 200 yards upstream of the repair yard where baulks of timber were floated in and left to season or stored until required. Directly across from the timber pond was a basin known as the "Dog and Duck", I seem to remember being told that sometime in the past a pub of that name had been located there. At the time I worked at the Top Yard the "Dog and Duck" basin was the site of Camplings Repair Yard owned and managed by the late Claude Campling. I have a host of memories of the time I worked there from 1949 until 1964.

Posted by Pete on 06/07/2007

I remember also my parents some 60+ years ago mentioning a pub named the Dog and Duck in this area. During my childhood we had the top yard and the shipyard so I can only surmise the bottom yard would be Goole Shipbuilders.

Posted by Shuffleton Streets on 07/07/2007

Believe it is so, that Dog and Duck may have been a "beer house" once upon a time, probably when the basin behind it was the canal boat mooring, in earliest days of Goole's history, ie. 1820s-1850s.

In the 1940s, it was home of Acaster family, although perhaps it began as a lock-keeper's canal-side cottage. There were small cottages for canal workers south of the present Dutch River and canal bridges. Called Bridge Houses 5 and 6 in 1901 census, lived in until 1940s, if not later.

Posted by John on 14/08/2007

Researching my family history, I found my great-grandfather worked on Tom Puddings but fell off and drowned at Altofts, July 1913. Name John Thomas Hyde age 36.

Posted by John on 15/01/2008

In 1986 I converted (by inserting a four foot centre section) a Tom Pudding to carry a 20 foot ISO container. It worked a treat and we got a plug on BBC TV. The idea was to start a service from Leeds to Goole, with up to eight puddings in a string (one 20 foot container in each), taking about a day to make the journey. The energy required was insignificant. Unfortunately BWB. had the redundant Tom Puddings (there were about 80) cut up for scrap, so there was nothing to convert.

Posted by Malcolm on 25/03/2008

Just visiting site for first time - I have worked in Goole as a ships agent since leaving school in 1968 and, correct me if I am wrong, but I believe that the floating hoist was called either No. 4 or No. 6 hoist?, No. 5 is the preserved hoist on the South Side of South Dock and as far as I know was always a fixed hoist with the Tom Puddings being stored in the South Dock Basin at 90 degrees to the hoist. No. 4 (or 6) floating hoist was almost directly opposite on the North bank in Albert Street where South Dock Terminals now operate.

I vaguely remember calling at a vessel loading at that hoist when I first started working and feeling a little queasy by the movement of the hoist when lifting loaded puddings. At that time the puddings were individually numbered for identification and our company was shipping coalite breeze/peas/beans/nuts (being descriptive of the size of pieces) out to Norway which continued for many years. There would be around 32-34 tonnes of coalite breeze (slag size) in a pudding and at the other end of the scale around 20-22 tonnes of nuts, (being bigger, lighter pieces and therefore less dense). Suppliers were Askern, Bolsover, Grimethorpe and Rossington works who delivered in lorries to canal side chutes for gravity tipping into the puddings, therefore you could have three or four different tonnages from each works in one pudding.

Ted Beevers, Eddy Chafer and Don Cawkwell were in the "coal office" as supervisors and they gave us a loading list with numbers identifying which puddings had been loaded into the ship. From that we were able to tie up what tonnage from which works had been loaded into each pudding to determine the final tonnage from each works. My abiding memory is of when the ship was nearly full the coal trimmers would go under the wings and ends of hatches (no box-shaped/self-trimming holds in those days) and disappear from sight as 30 tonnes was tipped into the hold where they were, after a minute or two you would see the coalite slowly shifting downwards as they dug their way out like moles, filling the void in the end/wings behind them until they resurfaced. Health and Safety would have a field day with those practices now.

The vessel in the third postcard (the light blue and white livery) is one of the Norwegian Rhine Line (NRL) fleet operated by Paal Wilson & Co. of Bergen. They used to carry coke or coalite for our clients to ports in the Norwegian Fjords and their vessels were regular callers and a common sight in Goole Docks from the mid-1960s until the late-1980s/early 1990s when the solid fuel trade almost totally declined. Looking at the structure of the vessel in the postcard she is one of their 850 to 900 tonne vessels and could be the TORPO, VOSSO, FOLLO, VENLO or any one of a myriad of sister ships (all ending in "O").

Posted by Corby on 26/04/2008

Throughout the history of Goole we read of the efficiency of the Tom Pudding and hoist system for the loading of ships but very little about the real heroes in this story. The Coal Trimmers. Ask the average man in the street and he would not begin to know what a coal trimmer is. A coal trimmer does what a miner does in reverse. In the old days given a handful of tallow candles to go beneath the deck and shovel coal into voids so ensuring the ship has a safe voyage with no threat of cargo movement. After a shift, coughing up coal dust long afterwards, like the miners.

My grandfather James Arthur Bunting had two good friends in his brother-in-law Charlie Shipley and William "Tash" Spencely, The latter took over the young family of my grandfather when he died at the age of 44. My father and many more young men continued in this thankless job often taking home the residue of coal dust. Within and without. Things became easier with the so called "self trimmer" design of ship but the job still needed the personal touch. I take my hat off to these unsung heroes.

Posted by Steve on 10/04/2013

I'm interested in the chain compressors that were fitted to some pans whilst in the dock (commonly called knacker bouncers). As far as I can see they were at one time fitted to two of the surviving pans but have been removed. If anyone knows where there is one, or likely to be one, I would be very interested. They were made of cast iron and fixed to the deck by four bolts. They had a bed with the shape of three chain links, and an attached hinged arm with a heavy round weight on the end to flip over and trap the chain. They were used like modern chain compressors for a quick release of the chain.

Posted by Stefan on 27/08/2015

I am a homebrewer and have decided to name my milds "Jebus" and a batch number. If my missus allows it.

Posted by John on 13/03/2017

My grandad Charles Oglesby was on the tugs pulling Tom Puddings to Goole

Back to Table of Contents

feedback@goole-on-the-web.org.uk